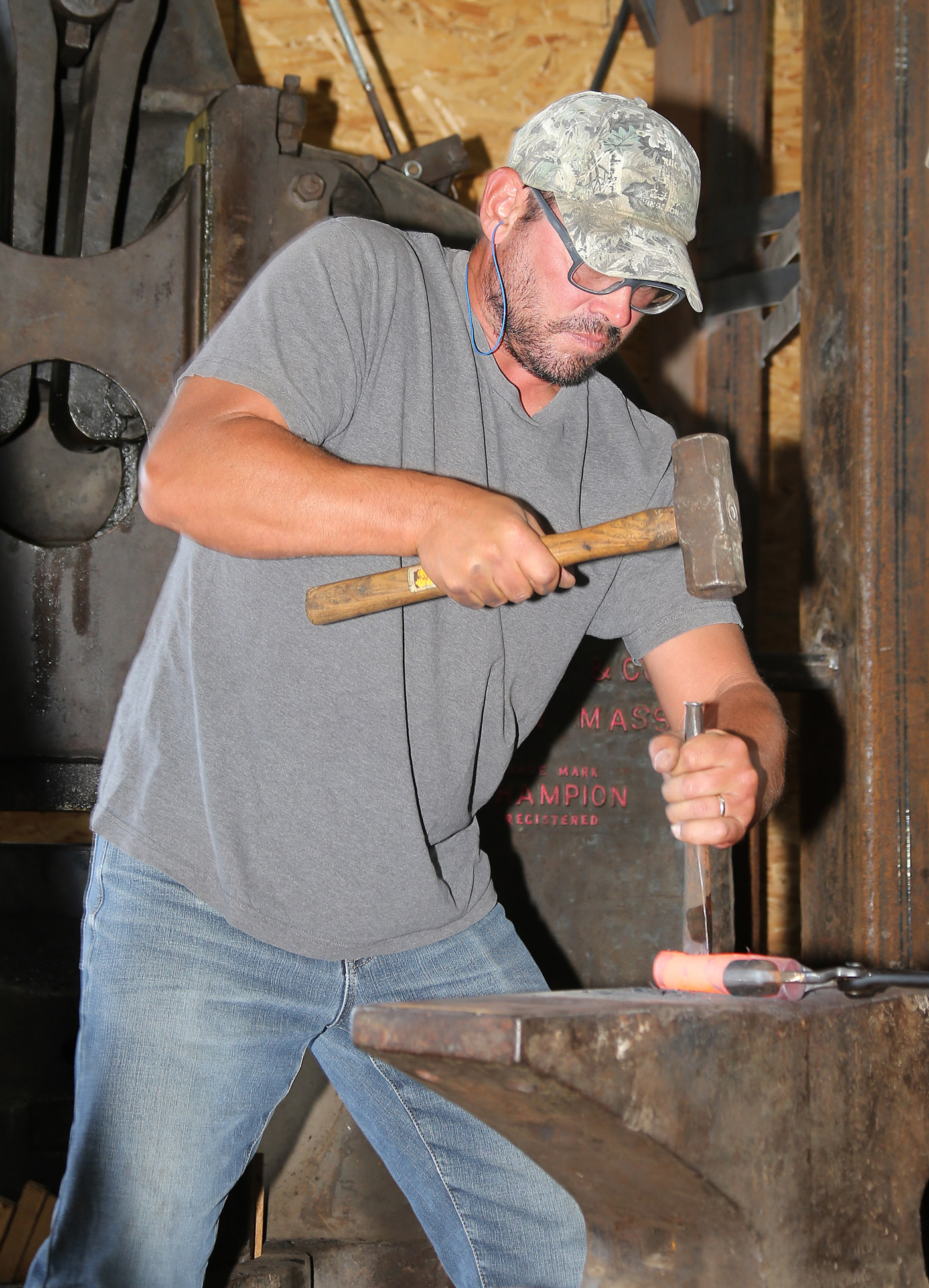

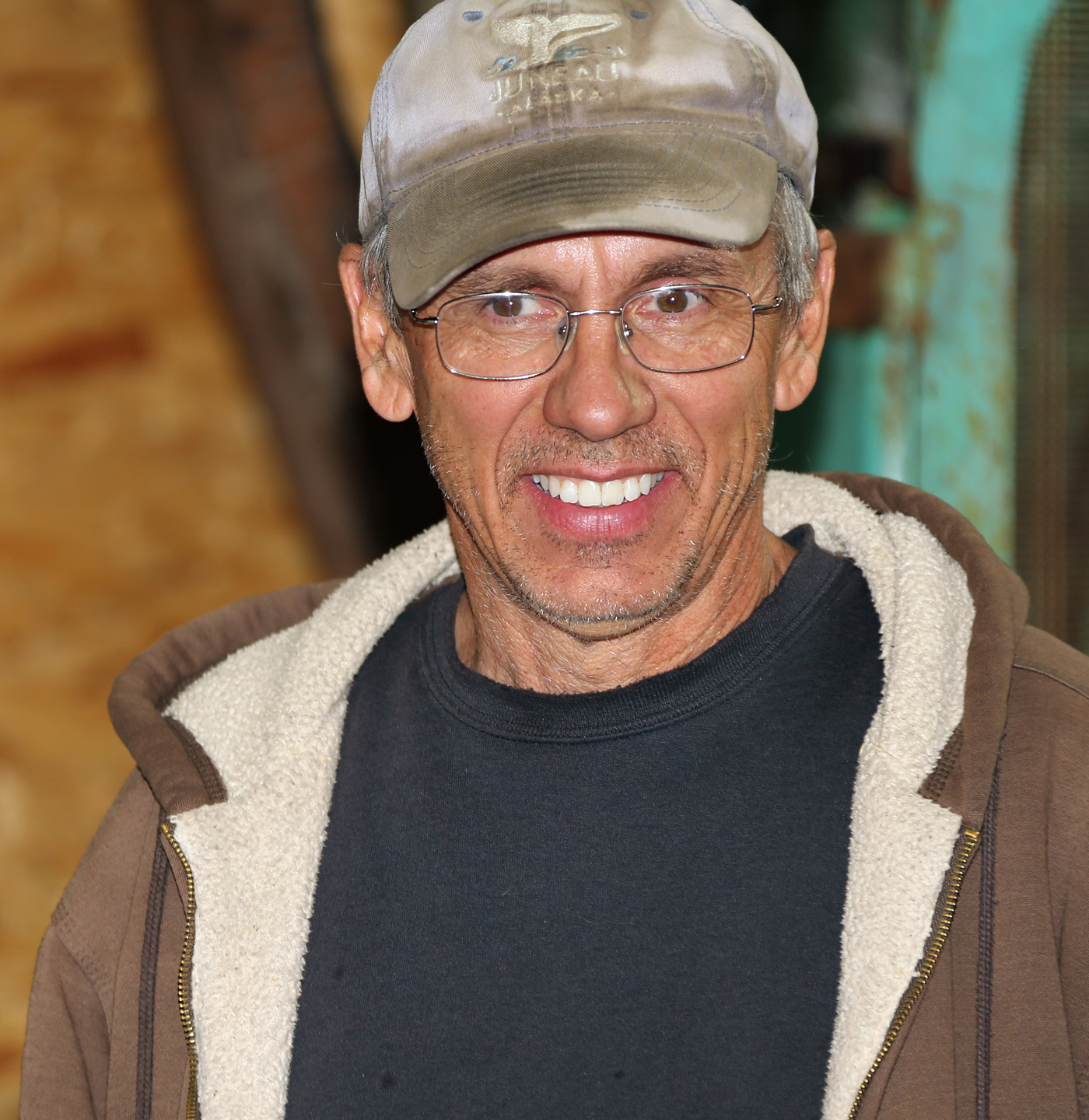

Fall Conference, 2019: September 20 - 22 at Al Lake's Moccasin Mountain Hammers, Lewistown, Montana John McClellan Demonstrating

Together with Mark Aspery, John McClellan was the founder of the ABANA National Curriculum Program.

John demonstrated toolmaking, and then using those tools to make other tools, taking advantage of Al Lake's remarkable collection of vintage power hammers.

Isolating material on a bar using a spring fuller under the 300lb Beaudry powerhammer

Finishing the end of the working end of a crank by upsetting.

Smoothing the isolation of material on a bar to form a perpendicular offshoot for the inner arm of a bending fork

Drawing out the above nubbin of steel into the inner prong of the bending fork---using a back-up plate in the vise to maintain straightness of the bar proper.

Completing the bending fork.

Drawing the edge of a hack sideways, using a fuller die under the Beaudry hammer

Smoothing the rein of one limb of a future pair of tongs using the flatter side of a combination flatter/fuller die under the powerhammer

The tongs, complete

Shaping a blob of steel, cut off from a piece of round bar, prior to making it into a die

Impressing a male butcher tool into the hot, soft blob of steel---to make a female die---with which to make future male butcher tools

Forming a semi-cylindrical groove into another hot blob of steel to make another die.

Isolating an area of steel in a hot bar using a spring fuller under the powerhammer.

Forging the new male butcher tool using the above-made female die.

In John's own words:

I got started in blacksmithing at the age of 8 when I inherited a forge and anvil from my grandfather. I read all the old books I could find on the subject and built my fires with small pieces of oak since I didn't have access to coal. The high school I attended offered a course in horseshoeing which I took my junior and senior years. This was the first time I got to use a coal fire. Since I already had years of experience in the forge the course was pretty easy for me and I helped teach it my senior year.

I continued to teach the Farrier class while I was attending the local Junior College. My major was agriculture, but the college had a great metal shop so I took most of the metals classes.

In 1978 I joined the California Blacksmith Association. Finally, I could talk to others that were doing the same things and having the same problems. The conferences I went to were overwhelming but exhilarating. There was so much to see and learn. I quickly picked up many advanced techniques from the professionals in the group. I have served as a board member, Vice President and President of CBA. I ran numerous Spring Conferences, doing my first while I was still in college.

I Joined ABANA in 1980 to attend the Santa Cruz Conference. That was my first exposure to smiths from around the country, and the world. It really opened my eyes to the possibilities.

In 1986 I graduated from CSU Chico with a B.S. in Agriculture with an emphasis in Industrial Arts and Business. I drove back to Sacramento every weekend to shoe horses and do any jobs that had come into the shop. The horseshoeing was my major source of income throughout this period as the market for good ironwork in Northern California was non-existent. It really helps to have a trade that can provide a reliable cash flow when you’re a student.

After I graduated from Chico I worked at Myers and Company, a custom ironwork shop in Basalt, Colorado and then went back to Sacramento to see if I could create a market for forged ironwork.

I started an educational exhibit at the California State Fair during the summer of 1987. This proved to be a great way to inform the public that forged metalwork was still being done and was available. Between the fairs, some articles in the local newspapers, and a TV story on the news, orders started coming in for everything from nice fireplace sets to large gates and railings. And most of the orders specified forged designs instead of tubing and castings.

I joined NOMMA in the mid 90's. Their focus on the business aspects of the metal industry was very helpful. Something the blacksmithing associations neglect. The Metalfab conventions are very educational and we won a silver award for the Cathedral Renovation at the 2007 convention.

I Joined the ABANA Board in the fall of 2009 to fill a vacancy. I took on the Journeyman / Education program at that time and have helped to establish the National Education Curriculum.

I have taught over 60 different classes in blacksmithing and had over 600 students over the years. I also do demonstrations for school groups and scout troops. The kids never seem to get enough of watching hot metal.

I started and continue to run McLellan Blacksmithing. I’ve run as a one man shop and have had as many as 12 employees. We’ve done projects ranging from “grandma’s” handrail for the front steps, to large commercial jobs like the Cathedral restoration in Sacramento and the new Cinematic Arts College at USC.

My business has forced me to become computer literate as well. All design work and drawings are done in AutoCad. We use Microsoft Office, and Corel Word Perfect. The use of email has expanded our world. Many of the quotes and designs are done by email now, allowing me to work from anywhere and send drawings and bids directly to the customers. As well as allowing contractors and architects to email me plans and specifications for jobs.

And then, members tried out the new processes John demonstrated, using some of Al Lake's exotic 19th century equipment:

Gallery of Members' work:

Bird in flight by Duane Bomar

Sculpture by Nathan Kimpel

Door knocker by Morris Hallowell

Herb choppper by Andy Olds

Adze hoe by Jem Blueher

Pair of blacksmith tongs, forged at the conference by John McLellan --- atop part of Al Lake's collection of vintage industrial tongs

And, a splendid time was had by all:

Locations are needed for future conferences. A stipend is available to defray your expense. If you would consider hosting a conference, please contact any NRBA board member.

Northern Rockies Blacksmith Association. Betty Ellis, Secretary, 2 Silvertip Place, Clancy, MT 59634 406 431-8227 bettyinmt44@gmail.com

NRBA Home Blacksmith News Board of Directors Past Conferences Future Conferences Education Program Library Touchmarks Member's Websites NRBA Articles Membership Application Links

Web editor: morris@hallowellco.com