NRBA Fall Conference 2017 --- John Simmons shop in Absarokee, Montana, September 15 - 17.

Brett Moten of Infinity Forge, Reno, Nevada demonstrating.

Squishing a bar of wrought iron under the hydraulic press. Forging a hammer head of wrought iron to be faced front and rear with forge-welded tool steel.

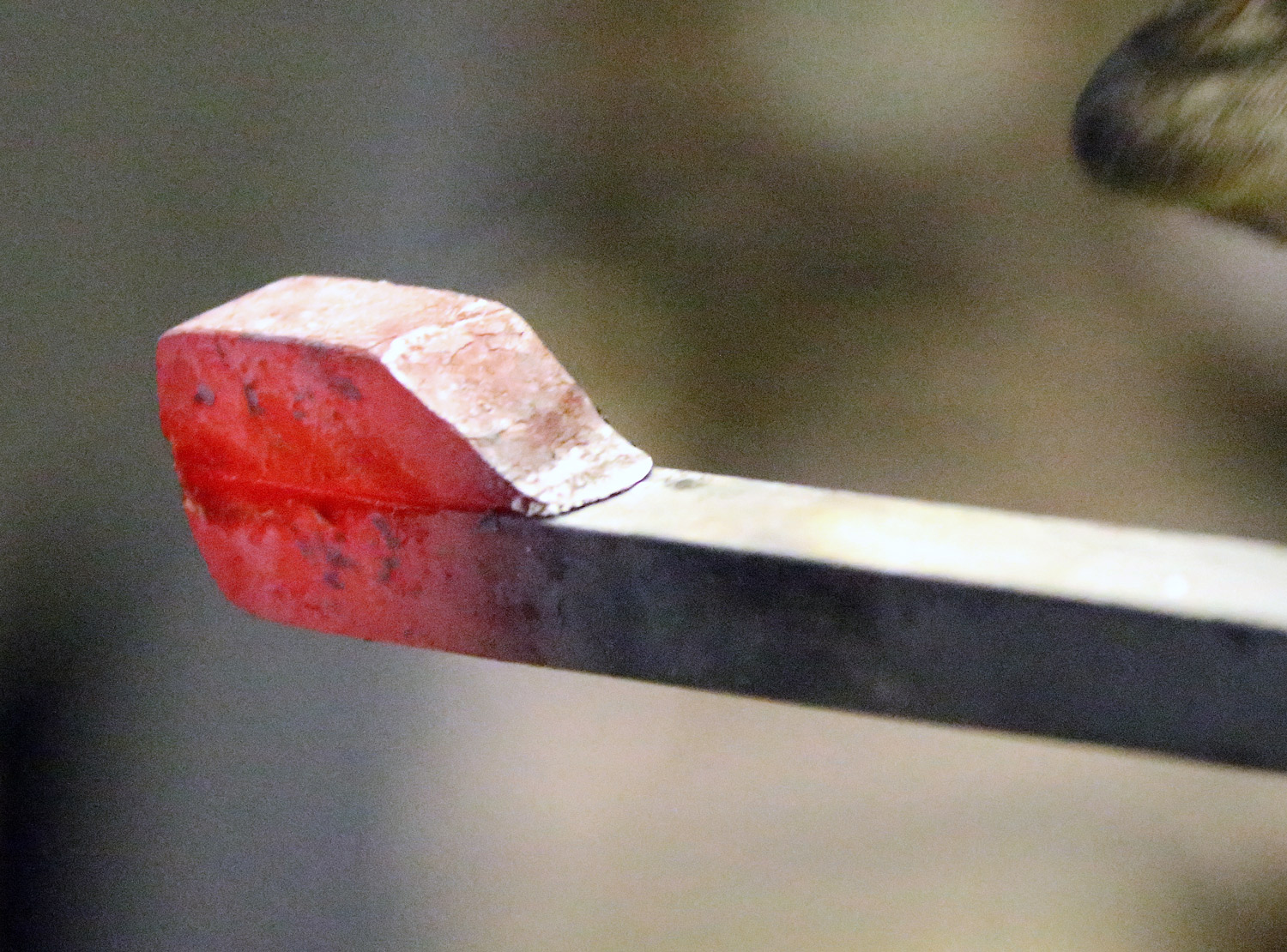

Preparing the tool steel hammer face; Andy striking.

Raising teeth on one side of tool steel hammer face with a V-gouge; better to grip the wrought iron hammer body when forge-welded.

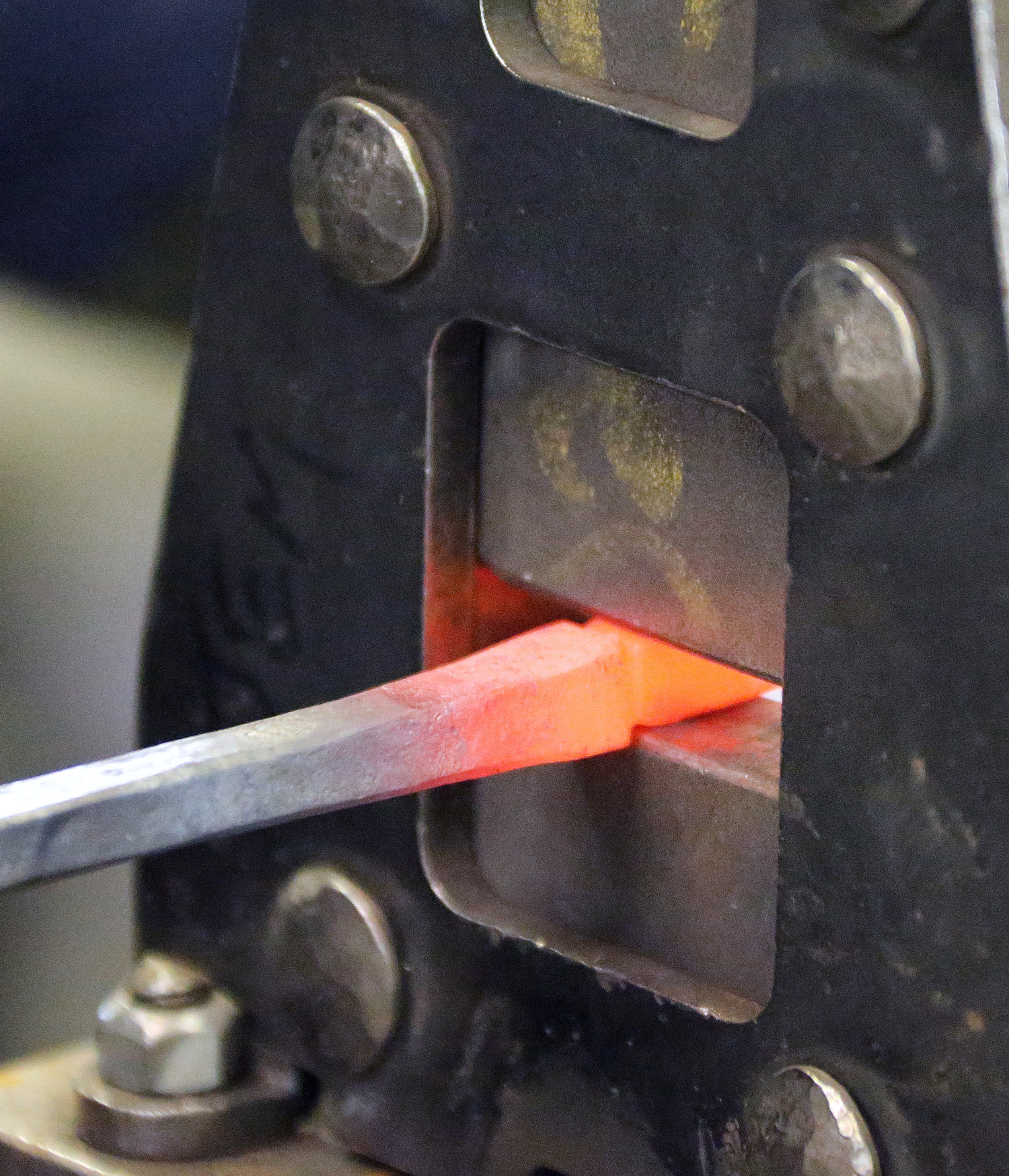

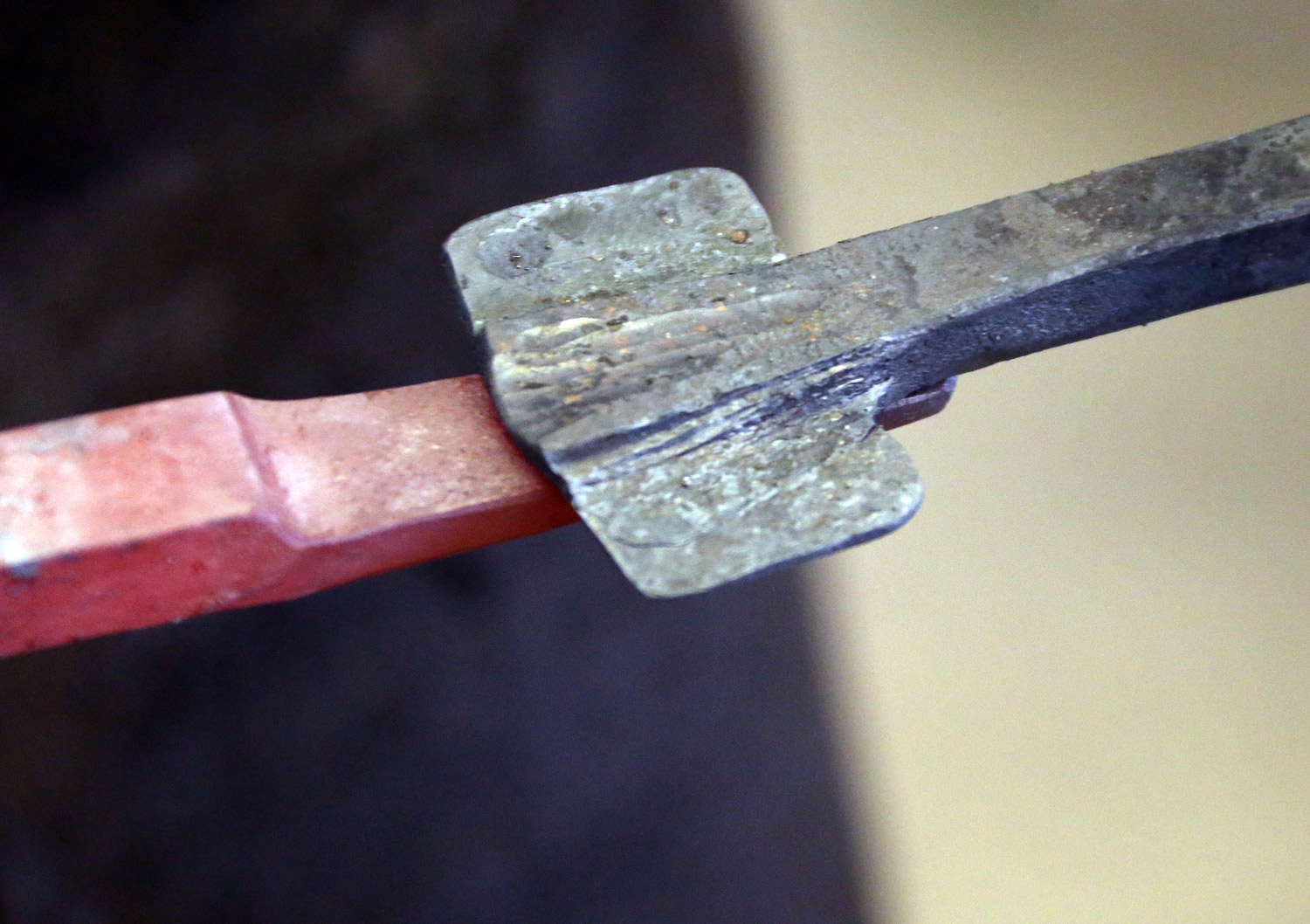

Positioning the fluxed tool steel face onto the wrought iron. Note the teeth raised in the tool steel to aid precise contact.

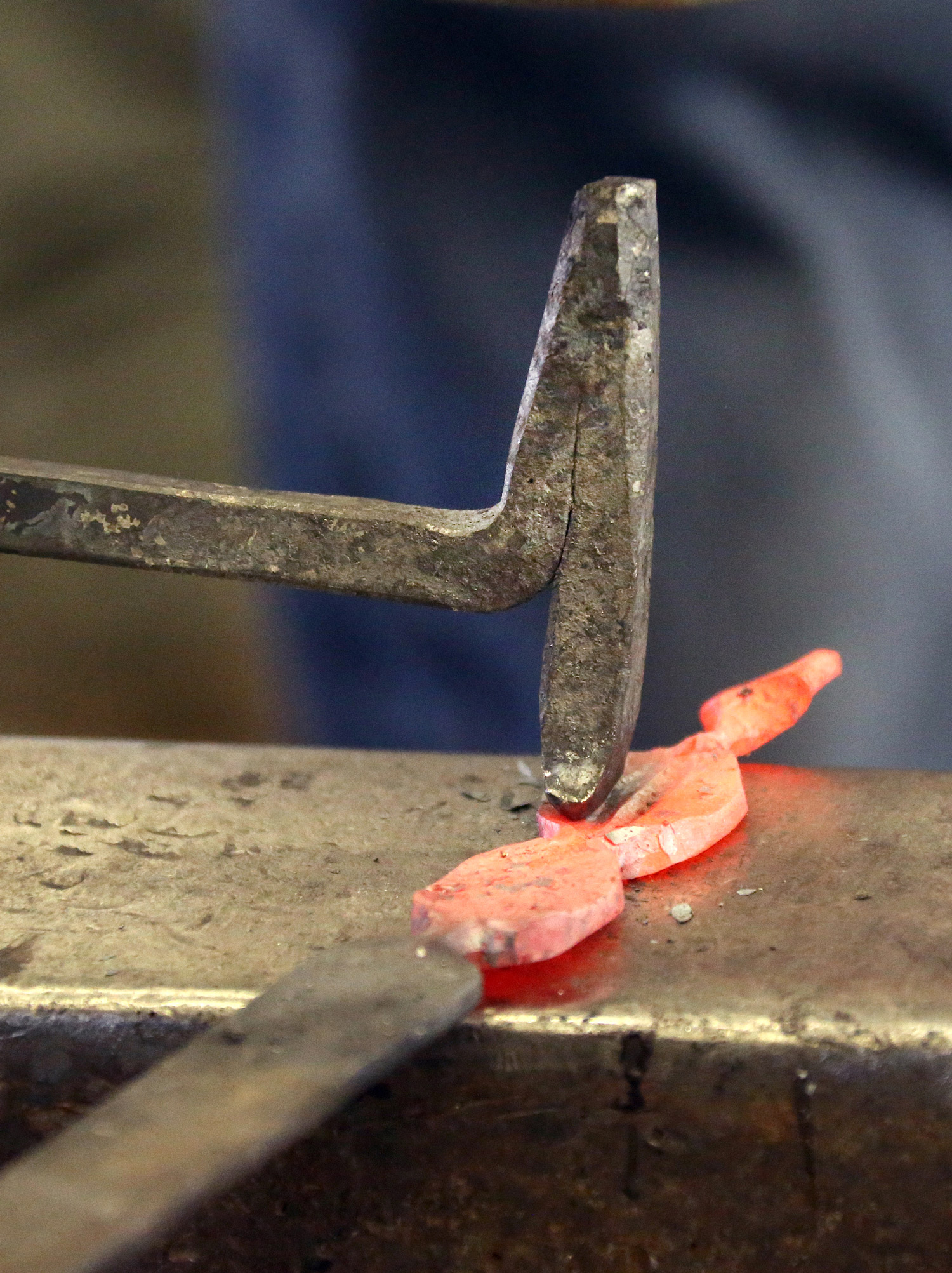

Making the forge weld.

Quick method of finding a centerline. Set dividers to an estimated half the width. Run them down the line from left side, then from the right. True center is midpoint between the two, very-closely-scribed lines.

Punching the hammer eye.

The hammer, complete. Note the visible grain structure of the wrought iron and the homogeneous tool steel forge-welded to the face and to the cross-peen.

Explaining the key-wedge joint.

A nick-and-fold forge weld to gain material at the end of a bar.

Making the second fold forge-weld.

Double-fold forge-weld complete.

Slotting a hole, preparatory to chiseling-out the web for a double-prong hanger.

Butchering a tenon-transition on the already-upset end of a bar with the "Smithin' Magician".

The wrought-iron base of the stand, hot-slotted to accept the upright---upset and tenoned at its bottom.

Key-wedge joint complete.

Spatula and stand, complete.

Making a forge weld; Joel assisting.

Beginning to form another type of wedge joint.

Beginning to forge the first petals for a dogwood flower, using handled texture-punch forged moments before.

Shaping a forged leaf in a swadge block, having used a sacrificial woodblock as a top tool.

Forge-welding a pair of leaves to the stem.

The completed dogwood flower.

About Brett Moten

Through the application of heat and force, this inanimate, cold, and obstinate material is transformed into an artistic language of shape, texture and permanence. As I grow as a person and an artist, I realize the importance of clear communication; through the metal my message is stated most clearly.

Using both traditional blacksmithing techniques and modern technology, I create both functional and fine works of art. A variety of metals are utilized including; steel, bronze, copper, and laminated metals. Wood, stone and glass can also be incorporated into the design.

Brett on the team with Roberto Giordani forging the fish at ABANA 2016 Salt Lake:

Together with Tim Cisneros, Brett Moten forged the rocking chair on display at ABANA 2012 in Rapid City,

Another wedge joint---part of a bench, on display at ABANA 2016 Salt Lake

See more about Brett at his website: https://www.infinityforgeinc.com/

Northern Rockies Blacksmith Association. Betty Ellis, Secretary, 2 Silvertip Place, Clancy, MT 59634 406 443-4712 bettyinmt44@gmail.com

NRBA Home Blacksmith News Board of Directors Past Conferences Future Conferences Education Program Library Touchmarks Member's Websites NRBA Articles Membership Application Links

Web editor: morris@hallowellco.com